Discover our range of products

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

About Van Raam

Van Raam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

Innovation at Van Raam

Innovation at a company means the introduction of new technologies in the production process or the production of new or improved products. At Van Raam we are always working on improving and renewing our products and processes. We are therefore proud of the bicycles that we have developed with the most modern production methods, since December 2018 we have been doing this in our new, modern bicycle factory. We have also won various innovation awards and Van Raam is a leader in the Smart Industry and Smart Working.

Modern and innovative company

Van Raam develops and produces special needs bicycles for both children and adults with a disability in a modern product line. We have been doing this since the 1980s and since 2004 in our modern factory in Varsseveld. Since the end of 2018 you can find us in our completely new factory. This factory is designed to be very sustainable. The factory is self-sufficient in energy as much as possible: this includes heat pumps, solar panels and extensive insulation measures.

Quality and sustainability are paramount at Van Raam. Van Raam strives for innovation and development in every department. In our modern company we apply an innovative company policy and we use modern techniques. Read the innovation per department below.

Curious how a Van Raam bicycle is made? Read more on the page 'How we make bikes'.

Designing

Our Research & Development department is always (re) designing Van Raam bicycles. When designing, they use the 3D drawing program called SolidWorks. In addition to designing, our R&D department is also engaged in research into the target group and the latest (bicycle) technologies.

Producing and assembling

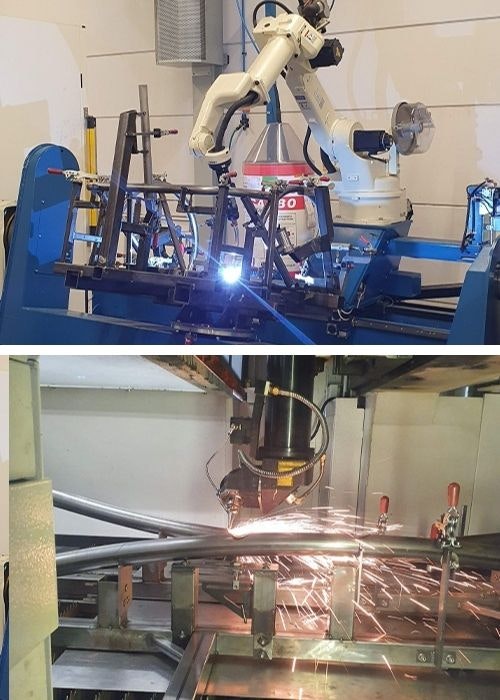

The production and assembly of our bicycles is done with modern techniques and machines:

3D Lasermachine for pipe processing

Computer-controlled CNC turning and milling machines

Welding robots

3D printers

Fully automated and modularly constructed Kardex lift system for order picking

Wheel making

Modern machines

At the Production Department, steel pipes are made into a frame. We use various innovative machines for this, such as CNC lathes and milling machines, a cobot and welding robots. We also have other machines, such as a 3D laser machine. We are number one in our market with these machines.

3D printing

Since 2017, Van Raam has been using 3D printers. Meanwhile, many bicycles in the Van Raam range have bicycle parts mounted that have been printed with a 3D printer. This can be a small part, such as a cover. But it can also be a large part, such as a cap for the chain guard. On almost every Van Raam bicycle a 3D printed part can be found.

With 3D printing, Van Raam aims to improve the production process and innovate. Nowadays we use a Multi Jet Fusion printer, FDM printers and an M2 Cusing Concept Laser 3D metal printer. Read more about the different printing techniques in the article 'Bicycle parts from the 3D printer at Van Raam'.

In 2021 Van Raam 3D printed a bicycle frame for the Husky children's tricycle for the first time. Read more about this in the article 'Childrens tricycle Husky from 3d printer at Van Raam'.

3D scanning

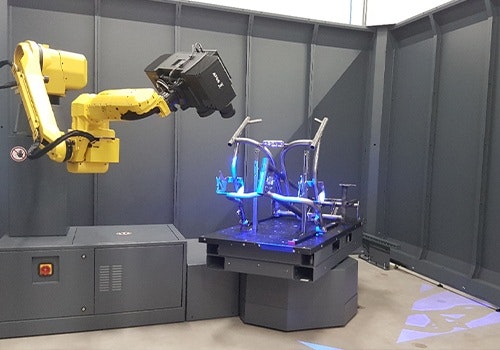

In early February 2020, a GOM brand ATOS scanbox was installed at Van Raam. The scanbox is a fenced-in room with a large turntable in the middle. Next to the table is a robot arm with a scanner. This scanner scans various objects on the disk using programmed movements and can therefore digitally capture these objects.

At the scanbox there is a computer with GOM software that can control everything. In addition, this software converts all scans created by an object into a digital 3D model.

With the new 3D scanner, bicycles and individual bike parts can be scanned to create a digital copy of the 'real' bike. By comparing it with the 3D drawings and designs that were made before the bicycle was manufactured, possible deviations can be identified. In this way, the production process can be optimized and the quality of the adapted bikes can be guaranteed. Learn more about the 3D Scanner in our article " Three major questions and answers of the Van Raam 3D Scanner”

Powder coating

The special needs bikes at Van Raam get their color by using powder coating, this is paint in the form of a powder. Powder coating is an electrostatic dyeing process where compressed air is used to spray negatively charged powder on a grounded workpiece. As a result, the powder sticks temporarily, after which it is melted in an oven. Thanks to the unique powder coating process, the powder is both reusable and solvent-free, and it also produces less hazardous waste than regular paint. When powder coating, we try to waste as little powder coating as possible and to work in an environmentally friendly way.

Modern warehouse system

We use a modern warehouse system to order pick the parts of our adapted bicycles. With the Kardex lift system we can store products in height and the automatic lift system automatically transports the correct parts to the warehouse employee.

Spoking wheels

At Van Raam we spoke all the wheels ourselves. We have modern machines to help with this. The spokes are placed in front of the correct spoke nipple and the spokes are put in the wheel rim, using a machine. Another machine places the rim tape on the rim and the spokes are also tensioned and balanced.

Line production

The adapted bikes from Van Raam are built up in three steps (module construction, pre-assembly and final assembly). For the assembly of our Easy Rider, Maxi and Midi tricycles and the Fun2Go double rider cycle, we work in line production. The assembly is divided into steps. Every assembly employee assembles his own "step" on the bike. A bicycle can be built up faster and you can work on several bicycles at the same time.

Test bench

We have a bicycle test bench, wheel test bench and a battery test bench. Prototypes are tested on the bicycle test bench and endurance tests are performed by our test engineer. Read more about our test bench in the article: 'Test engineer Gebby and the bicycle test bench at Van Raam'.

Interested in our entire production process?

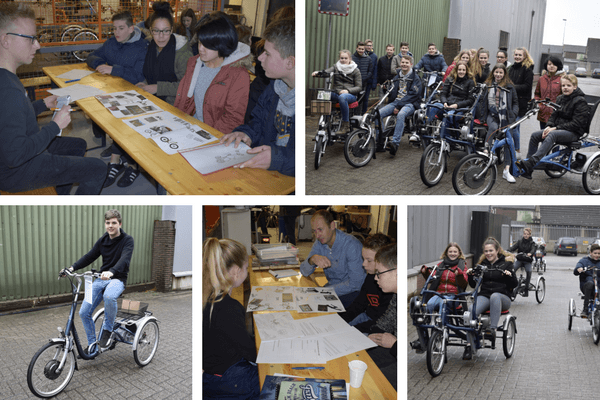

Van Raam bike test track

At our bicycle factory in Varsseveld it is possible to try all adapted bicycles from the Van Raam assortment during a free test ride. To help our customers getting to know our adapted bicycles in the best and safe way, Van Raam has designed a bike test track with various traffic obstacles on which customers (together with a technical adviser) learn to get used to cycling on an adapted bicycle.

In addition to the fact that it is nice for customers of our showroom to experience various traffic obstacles on an adapted bicycle, the bike test track also has many advantages for the Research & Development department. For example, they use the test track for all kinds of bicycle tests.

Curious about the bike test track and want to read more about the formation?

Van Raam 360 degree/3D photos

On almost all productpages of our bikes you can find, next to other photos, 360 degree/3D photos of the Van Raam custom bikes. Learn in the article "360 degree and 3D photos of Van Raam special needs bikes" what 360 degree/3D photos are and where you can find and view them on a product page of a Van Raam bicycle.

Van Raam Silent pedal support system

Our R&D department and the electrical department developed their own electric pedal support system in 2011: the Silent System. The motors, the batteries, the controller, the Smart display and the software were developed by and for Van Raam. With this system it is possible to, among other things, ride almost completely silent, to cycle both forwards and backwards and the system can be connected to the Van Raam E-Bike App. Read more about our pedal support system here.

Smart Industry

"The development of Smart Industry means the far-reaching digitization and interweaving of devices, means of production and organizations (the 'internet of things'), creating new ways of production, new business models and new sectors." (source: www.smartindustry.nl)

Many companies are already involved in Smart Industry, but five active entrepreneurs, including Van Raam, form the "leading group BOOST". BOOST is the action agenda for Smart Industry in the Eastern part of the Netherlands and prepares the East of the Netherlands for Smart Industry. They are a source of knowledge and inspiration for other entrepreneurs in the field of Smart Industry. They have created an Action Agenda with which they help to integrate smart industry into the Eastern Dutch corporate culture.

With the development of Smart Industry, Van Raam has started digitizing, automating and robotizing a lot. This can be seen in the purchase of new machines, such as in the laser machine and welding robots. The employees were involved in this process, they soon noticed that the robots would only take over the "boring" and repetitive work and that craftsmanship remains necessary.

In the video below you can see and hear Marjolein Boezel, financial director at Van Raam, about Smart Industry.

Read more about smart industry and social innovation the article 'Van Raam and Boost working together on the future'

Smart Working

Smart Working is everything that employees and companies do to to increase their agility. Companies and organizations do this by continuing to learn and constantly adapt to technological developments.

Digitization, robotization, big data and other innovative technology entail many changes. Employees are happy about these developments and expect the work to become more challenging and fun. Let the robots come!

On the FME website and in the "Smart Working" magazine, Marjolein talks about this Smart Working at Van Raam. Marjolein talks about trust and attention, self-development, cooperation with schools and students, innovation at Van Raam and the release of employees. All parts of Smart Working.

Internet of Things (IoT)

The "Internet of Things" is a trend in which devices and objects are equipped with sensors and are connected (wirelessly) to each other via the internet. A few examples: a parking space that communicates availability or the smart meters that help to reduce energy consumption and a self-driving car.

On 25 June 2018, the 'Kamer van Koophandel' (Chamber of Commerce) presented the Innovation SME top 100, and it was announced that Van Raam also conquered a place in the top 100 with a special bicycle. Van Raam was nominated with the smart, personalized bicycle and variable pedal support. The Internet of Things (IoT) is used for this. Patients can use the IoT bicycle in a rehabilitation program by sharing the information with the rehabilitation doctor or physical therapist. Depending on the course of the rehabilitation, the settings of the bicycle can be adjusted from a distance . With the submission of the smart IoT bicycle, Van Raam finished in 90th place in the innovation top 100. In the election of the public award, Van Raam finished in the top 10.

EMBIPRO

Van Raam joined various regional partners in the innovative EMBIPRO-project. The goal of the EMBIPRO-project is to make products within healthcare, industry and Leisure smarter. This collaboration aims to improve the quality and experience of the products and services provided. The specific focus is on health and well-being, sustainable energy use, efficient use of raw materials and a safer working and living environment.

By collecting data from sensors in a Van Raam bicycle and analyzing this, we can have more information about the use of Van Raam bicycles and the battery. With this information we can improve our future bicycles and batteries, but we can also advise our customers on the use of our bicycles and batteries to extend the life and to minimize maintenance and service costs.

Sustainability and environment

The new Van Raam bicycle factory has a sustainable climate system. The Van Raam bicycle factory has a modern installation system that has been installed by Heva, an installation company. The sustainable climate system consists of 25 closed soil sources, which are 130 meters deep in the ground, and filled with a glycol mixture, 2 heat pumps with each having a buffer vessel suitable for 1500 liters of water; one for hot water and one for cold water. Furthermore, the climate system is supplemented with air-conditioning (from Carrier) and two air handling units on the roof (from Mark Climate Technology). An extra air handling unit from Lutec has been installed in the production hall. The factory is equipped with, among other things, insulation material (from Kingspan), HR+++ insulated glass and solar panels on the roof. These solar panels provide more than the necessary electricity in the factory.

Investments have also been made in a new paint shop that uses at least 30% less gas. The remaining heat from the paint shop is used to pre-heat frames to make the (energy-intensive) coating process as efficient as possible.

Van Raam's environmental policy focuses on constant improvement and preventive measures to prevent environmental pollution. This is achieved by, among other things, separating waste and striving to limit environmental factors.

Read more about the circular and sustainable policy of Van Raam in the article 'Circular and sustainability policy of Van Raam'.

Curious about the sustainable climate system in the Van Raam factory?

Corporate Social Responsibility

Van Raam is aware that CSR is the way of sustainable business. The main activity of Van Raam is in itself socially responsible: making an environmentally friendly means of transport for people who cannot use a standard product for this. Van Raam assesses the effects of business activities on people (people), the environment (planet) and business operations (profit). Choices are consciously made to find a balance between these three Ps. These factors are also weighed against each other in international cooperations. Van Raam also endorses the the Code of Conduct for Medical Devices and we meet all the requirements for the Nationaal Hulpmiddelen (National Services) quality label.

Van Raam and the Innovationhub Innovar

From 2012, Van Raam, together with the companies Contour AS and Waterkracht, started its own Innovation Hub, called Innovar (Innovation Varsseveld). For this Innovation Center, there are several students from different study programs and levels at Van Raam each period who carry out an internship or graduation assignment. At van Raam, it's very important to continue the development of existing bicycles and the development of new products and solutions. We like to do this in combination with students.

Innovar is led by a project manager who is specifically for the students. In addition to the project manager, there is also a substantive supervisor from Van Raam who can guide the students. The students also get the opportunity to collaborate with other students and share their experiences. Innovar is on the one hand to properly guide talented students with a fresh perspective during an internship, project or graduation assignment and on the other hand it is the task of the companies to make students familiar with the business world. In addition, it is a nice way to make Van Raam known to the students and for Van Raam the students are potential employees.

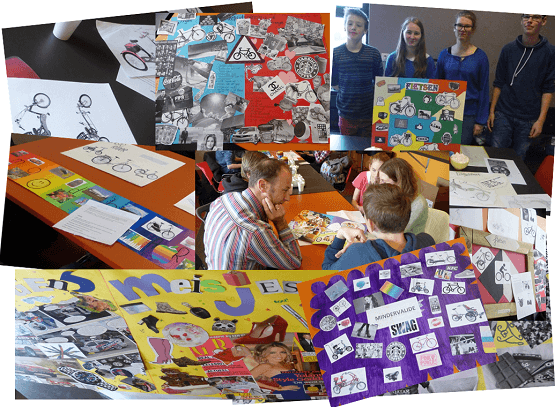

Working together with students

In addition to our Innovationhub, we often work together with students to introduce young talent to the bicycle industry. High school students regularly come to Van Raam to "Practice Learning".

Awards

Van Raam has won various awards. Read more about these awards on our Van Raam Quality Labels & Awards-page.

Van Raam custom bikes test winner by Norwegian government (2020)

Van Raam's pedal support winner ExtraEnergy test (2018-2019)

With the smart personalized bike in the MKB (SME) Innovation top 100 (2018)

Top 10 public award MKB (SME) Innovation top 100 (2018)

Van Raam bicycles rated best in test by independent commission of the Norwegian government (2017)

Districtswinner Smart People Award (2015)

Koninklijke Metaalunie: Winner Smart People Award (2015)

With the Gocab in place 14 MKB (SME) Innovation top 100 (2012)

Innovation award GoCab (2011)

GIO-award GoCab (2011)

Tros Radar: de Warme douche (hot shower) (2011)

Do you have any questions?

We are happy to assist you! Please check our contact page or contact us directly using the options below.